- Home

- Fulfillment Pro

- Fulfillment Pro: Quality Control

Fulfillment Pro: Quality Control

This FAQ will go over the Quality Control feature in Fulfillment Pro.

Quality Control Set Up

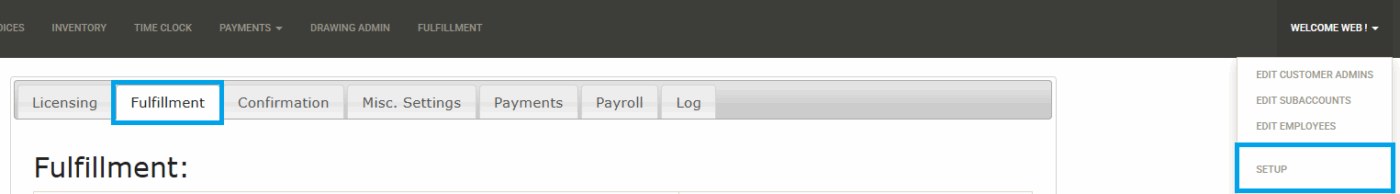

To set up quality control failure codes and priorities, go to the company website > Set Up > Fulfillment > Quality Control.

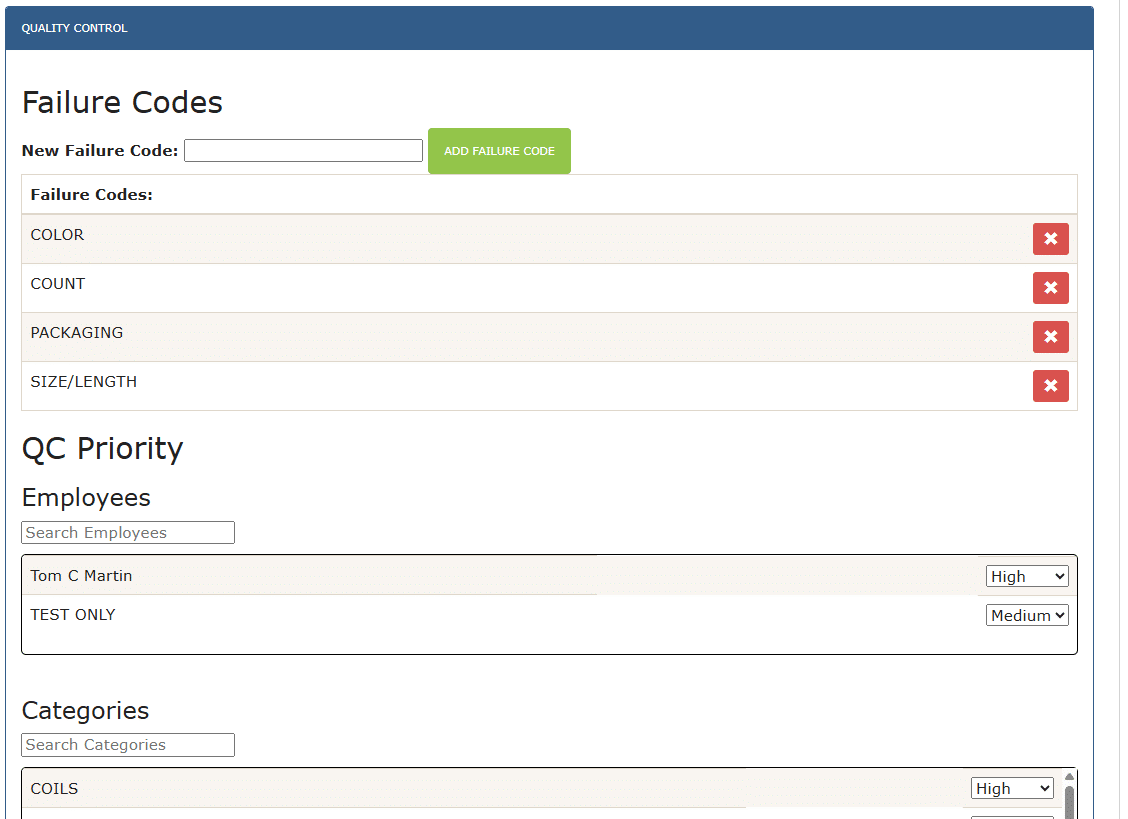

- Failure Codes – Failure codes are used to show what type of error caused the quality control to fail.

- Priorities – Priorities can be set on Employees, Categories, and Subcategories. This will be used to group the pull labels by High, Medium, and Low priority in the review list.

- The priorities are used to mark which items or employees have a low or high risk of being missed.

- New categories, subcategories, or employees are set to medium priority by default.

Enabling Quality Control

If any user has access to the Quality Control Admin screen, all users will then have access to the “Failed Labels” screen, where they will be notified if one of their labels failed the quality control check.

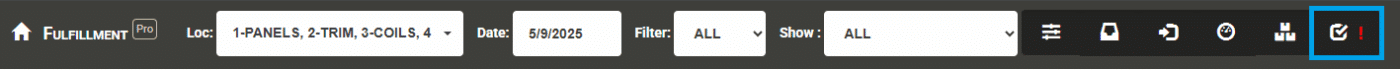

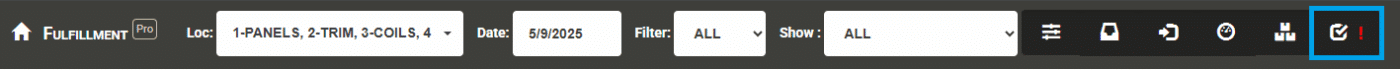

A red exclamation mark (!) will be shown when there is a label to be resolved.

Quality Control Admin

To give a user the option to review pull labels and mark them as pass or failed, go to the employee’s Fulfillment settings and enable “Use Quality Control”.

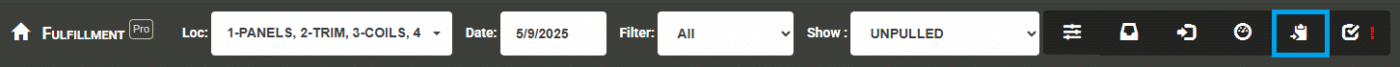

The following button will then be shown for the login(s) it is enabled on.

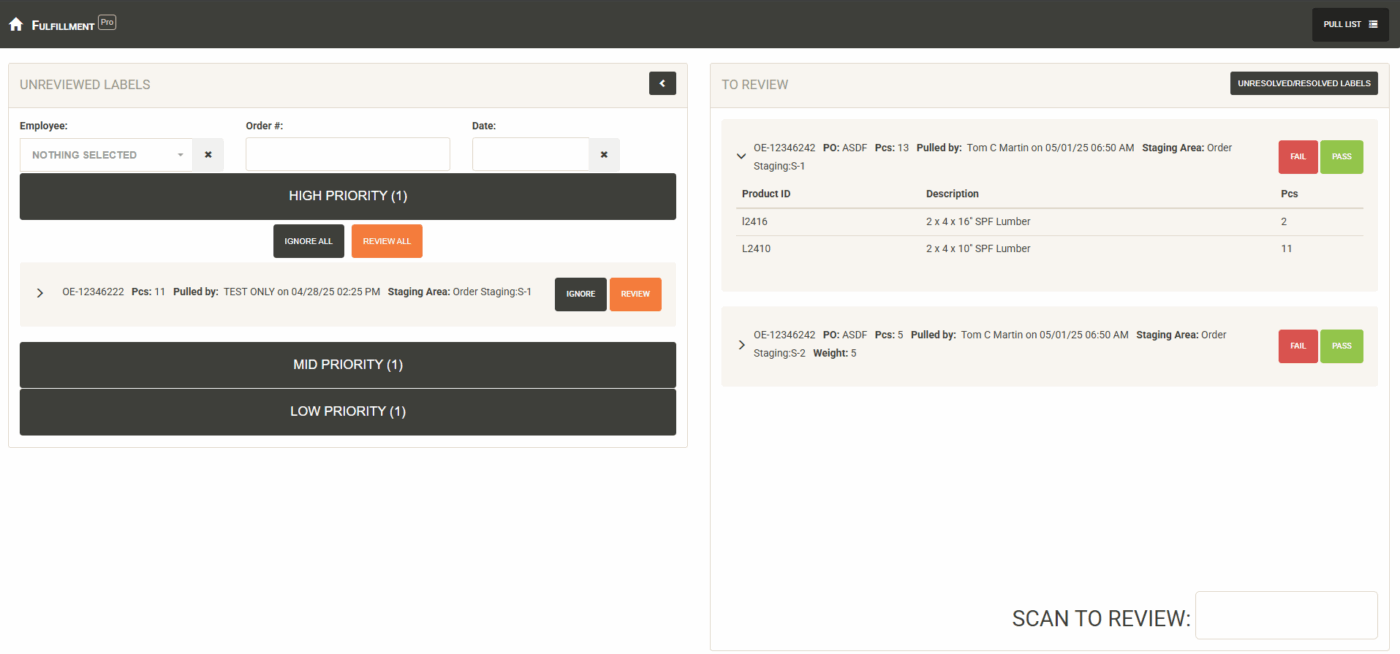

The quality control admin shows pull or pack labels to be reviewed, grouped by Low, Mid, and High priority. Labels can be marked to be ignored or to review them. Labels can also be scanned in to review them, using the “Scan to Review” field in the bottom right.

Pass/Fail Labels

If a label passes, it will be marked “Pass” and the label will be removed from the list.

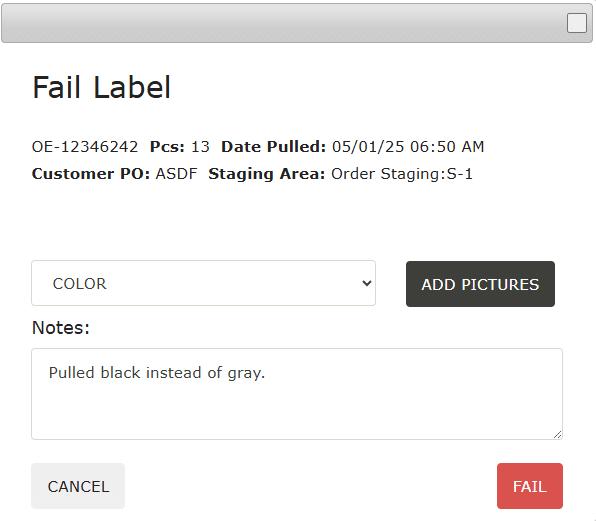

If a label fails, it will be marked “Fail” and a pop up will be shown for the user to select the fail code, add pictures, and enter a note to explain why it failed. This will be shown to the employee that pulled it. After a failure is resolved by the employee, it shows back up in the main list of labels to potentially be inspected again.

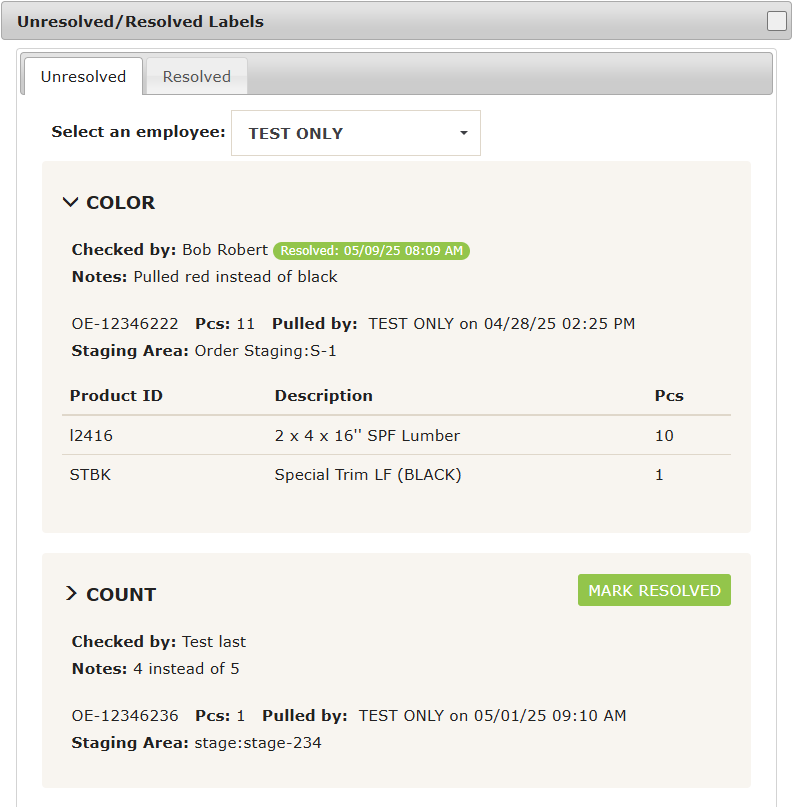

To look at the reviewed labels, click the “Unresolved/Resolved Labels” button. From here, labels can also be “Unmarked as Failed” in case they were mistakenly failed.

Reviewing Failed Labels

After a label is marked failed, the employee will see the failed label in their “Unresolved Labels” list. This is based on the employee they have selected on their Fulfillment Pro employee selector.

The fail code will be shown at the top, with the notes below explaining why it failed. Clicking the arrow will expand to show the products that were on the failed label. After it has been resolved, the time stamp will be shown and the employee who reviewed it will have it show up in their list again to be reviewed. Once the list is loaded again or refreshed, resolved labels will be shown in the “Resolved” tab.

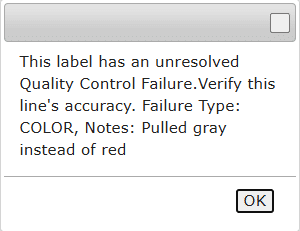

Failed Label Error – Scan To Ship

If a user tries to scan a label in Fulfillment Pro to ship it, and the label has an unresolved Quality Control failure, the following message will be shown:

This label has an unresolved Quality Control Failure. Verify this line’s accuracy. Failure Type: [FAILURE CODE], Notes: [FAIL NOTES]

Reporting

Reports can be built off of the quality control failures to help identify problem areas. Contact Paragon Support to get a report set up.

Contents

Categories

- Purchase Order and Vendors (20)

- Production (37)

- Order Entry and Customers (79)

- NEW! (8)

- Job Costing (16)

- Inventory and Pricing (96)

- General (57)

- Fulfillment Pro (30)

- Dispatching (24)

- Administration and Setup (43)

- Add-Ons and Integrations (31)

- Accounting (55)