- Home

- Production

- Machine List

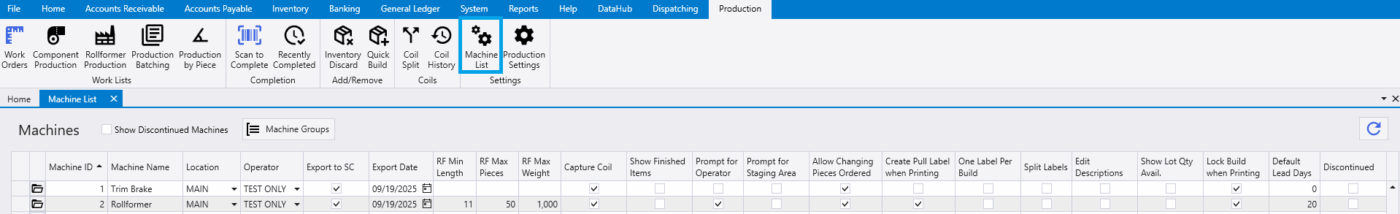

Machine List

This FAQ will go over the machine list settings in Paradigm ERP, this is used to set up machines for production. Information on machine groups can be found here: Machine Groups

Machines

- Machine ID – The unique machine ID, this is automatically set when the machine name is entered.

- Machine Name – The machine name shown in the production screens.

- Location – The location (warehouse) that the machine is located at.

- Operator – The employee that operates the machine.

- Export to SC – Export builds at the machine – more information on exporting can be found here: Connex, Variobend, Eclipse

- Export Date – Data will only be exported if the date is today or before the set export date, when exporting to a rollformer control software.

- RF Min Length – If the items on the build are shorter than the minimum length, the items will nest together when exporting to a rollformer control software until it reaches the minimum length.

- For example if the minimum is 3 ft, then two 2 ft pieces would be exported as one 4 ft piece.

- RF Max Pieces – If over the max pieces, it will export and then put it on hold and the field will be highlighted in red.

- RF Max Weight – If over the max weight, it will export and then put it on hold and the field will be highlighted in red.

- Capture Coil – Information on this can be found here: Capture Coil

- Show Finished Items – Finished items will be shown until all builds are completed at the machine.

- Prompt For Operator – Prompts the user to select the current operator after build completion.

- The operator selection drop down shows the list of employees.

- Prompt For Staging Area – Assigning Staging Areas In Production

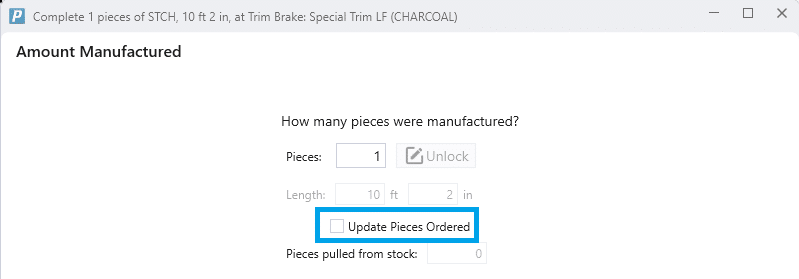

- Allow Changing Pieces Orders – Allows the user to change the pieces ordered, when adjusting the number of pieces manufactured.

- Create Pull Label When Printing – Creates a pull label when printing, this allows for the label to be scanned in Fulfillment Pro.

- One Label Per Build – One Label Per Build

- Split Labels – Line Split By Label

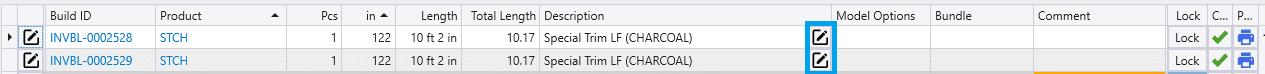

- Edit Description – This will show an edit button on the description field in production.

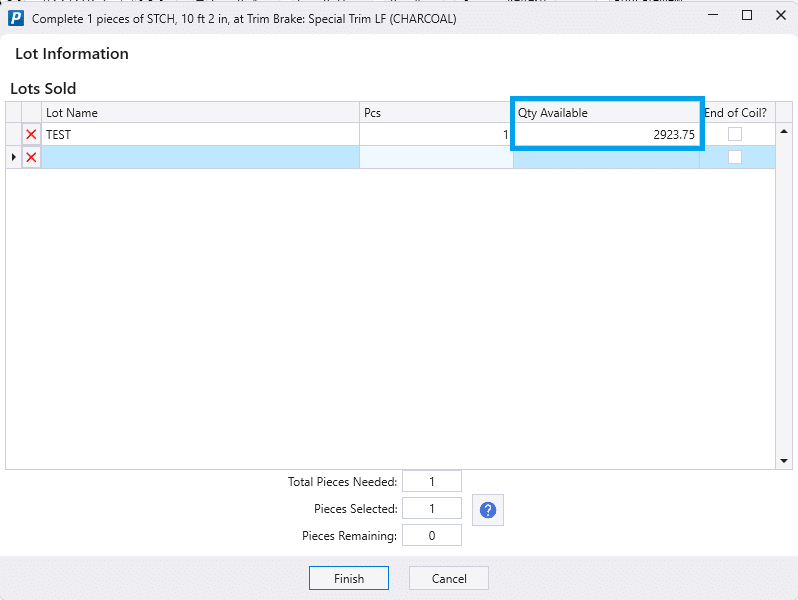

- Show Lot Qty Avail. – Show the available lot quantity on the lot selection screen.

- Lock Build When Printing – Locks the build after printing, instead of the production user selecting “Lock” as they begin to work on that build.

- Default Lead Days – Default lead days set when the production screen is opened for the machine.

- Discontinued – Discontinue the machine – once a machine is discontinued, it will not be shown in the production screen drop downs.

Contents

Categories

- Purchase Order and Vendors (20)

- Production (37)

- Order Entry and Customers (79)

- NEW! (8)

- Job Costing (16)

- Inventory and Pricing (96)

- General (57)

- Fulfillment Pro (30)

- Dispatching (24)

- Administration and Setup (43)

- Add-Ons and Integrations (31)

- Accounting (55)